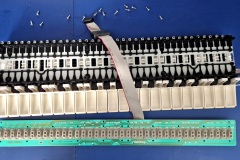

Novation Ultranova

A seemingly simple repair: replacing an incremental encoder.

Unfortunately, in this device the encoder works in an unusual configuration — pins A and B are neither pulled up to VCC with resistors nor connected to GND through capacitors; instead, they seem to be cross-wired.

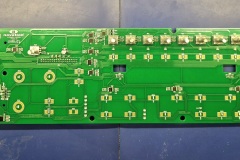

As a result, even after trying several encoder types, the instrument would randomly jump a few positions during adjustment. Since no circuit diagram was available, it was necessary to purchase multiple encoders (with different counts per revolution) and test them to find a suitable one. Finally, a branded encoder was used, providing 15 pulses per full shaft rotation. Interestingly, the front panel PCB also had to be resoldered, because it contained cold solder joints and the display did not always initialize correctly, depending on the mechanical stress of the enclosure.